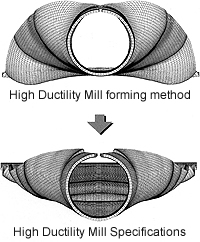

Features in Pipe Forming

- Little processing strain in the pipe circumferential direction, creating greater uniformity

- No repeated bending deformations

↓

- Realization of low-strain forming

The realization of nearly ideal forming enabled minimization of squeezing in fine passes and sizing during forming.

- Realization of thin-walled items

Low-strain forming enabled manufacturing of wall thicknesses down to 0.6 mm (1/D = 1%) whereas they the minimum used to be 1 mm.

High Ductility Mill Specifications

| Outer Diameter Range |

25.4~101.6mm |

| Wall Thickness Range |

0.6~3.0mm |

| Length Range |

3.5~7.5m

|

| Welding Method |

High-frequency electric resistance welding

|

| Tube Manufacturing Speed |

Max.100m/min.

|

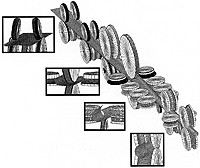

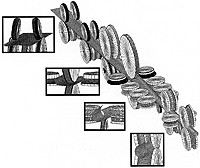

Full view of the High Ductility Mill

Example low-strain roll placement

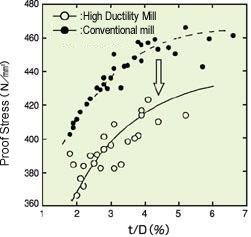

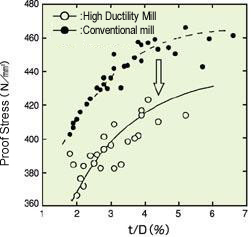

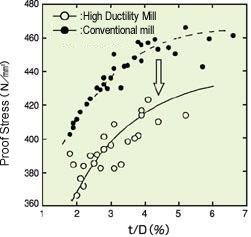

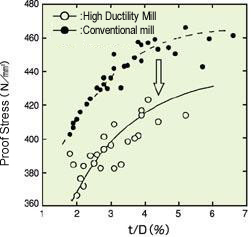

Examples of Pipe Performance Increases from the High Ductility Mill

Results of tensile test on SUH409L steel tube (0.2% proof stress change)

Results of tensile test on SUH409L steel tube (elongation change)