We provide highly safe and durable carbon steel tubes for machine structures.

Demand for carbon steel tubes for machine structures is increasing recently. As examples, there may be mentioned hollowing out materials due to increasing needs of weight reduction and replacement for pressing sheets for reducing the number of parts.

Materials available include:

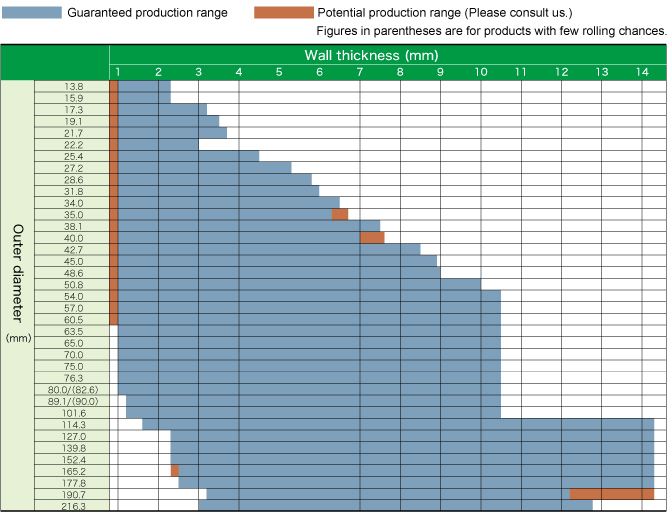

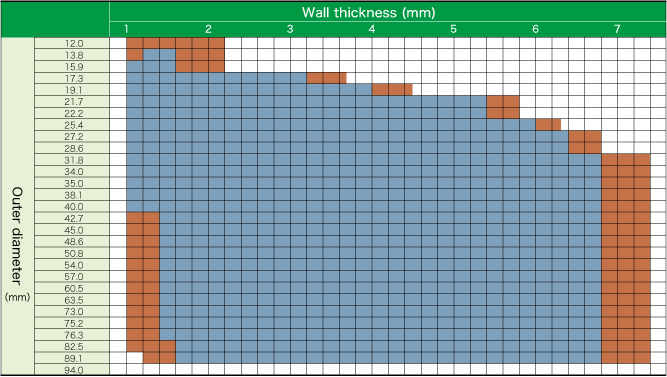

We have tube-manufacturing equipment that can manufacturing tubes up to a maximum outer diameter of 216.3 mm as well as a variety of cold drawing equipment allowing us to provide a high level of dimensional accuracy, including for special dimensions.

We can design individual specifications that meet requirements through the use of heat treatment and finishing equipment.

We also use carbon steel tube, high-tensile steel tube, stainless steel tube, and other types of steel tube manufactured in-house to provide shaped tubes finished in a variety of shapes.

We offer integrated quality control, from steel manufacturing through to the completed product.

We also have a full assortment of non-destructive inspection equipment for ultrasonic and eddy current testing.

Tags and/or stencils are used for identification management of all items. (Customer numbers are displayed as ![]() .)

.)

NIPPON STEEL CORPORATION Group has put in place a cooperative framework for component design and development based on its facilities including a Mechanical Tube Testing Center (evaluation and testing facility) and hydroforming machine (experiment facility).

Carbon steel tubes for machine structures are used in a wide variety of areas, especially components for automobiles and construction machinery.

Types |

Applications |

|

Cylinders and rods |

Four-wheel vehicles: |

|

Construction machinery |

Frame, pillars, etc. |

|

Machine structural components |

Machine tool pillars and connecting members, precision machinery components, etc. |

|

Other |

Bicycles, furniture, etc. |