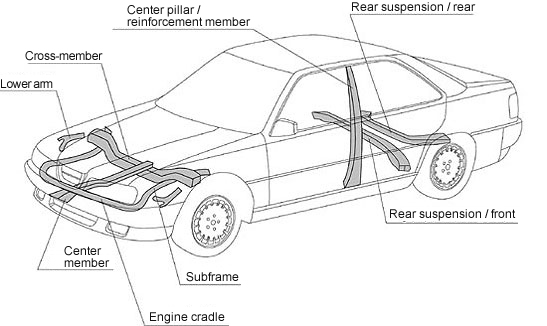

Hydroforming is a method for processing closed section structures like pipes by applying hydraulic pressure to the inside of the structure.

When compared with the manufacturing of closed section structural parts using metal stamping, this method provides the following advantages and can be expected to result in substantial cost savings and greater strength:

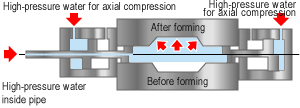

There are two major methods of hydroforming: low pressure and high pressure. We can conduct all of the tests on processing methods indicated below with our experimental unit.

| Molding | Comparison of Methods | Equipm-ent cost | ||||||

| Internal pressure forming | Axial compre- ssion |

Press forming | Tube expan- sion rate |

Comp-lex shapes | Corner Radius | |||

| Low pres- sure |

(in combi- nation with pressing) |

○ | ○ | △ | △ | ○ | ○ | |

| ○ | △ | △ | △ | ○ | ||||

| High pressure | ○ | ○ | ◎ | ○ | ◎ | ▲ | ||

| Mold closing |

Method | Hydraulic press |

| Mold clamping force |

3500T | |

| Daylight | 1600mm | |

| Stroke | 1000mm | |

| Includes vertical die cushion* | ||

| Forming pressure |

Normal max. | 3000atm |

| Axial compre- ssion |

Method | Dual double acting cylinder* |

| Axial compressive force | (100T + 100T) × left and right | |

| Forming dies |

Size | MAX1800×1800mm |

| Moving bolster | ||

The following peripheral technologies can be used with the hydroforming experimental unit:

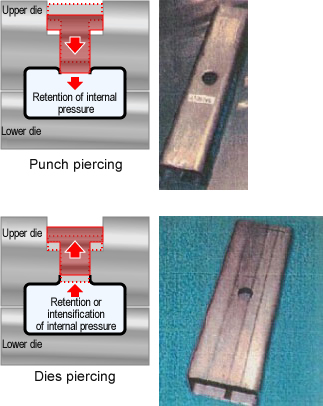

(1) Hydropiercing technology

Operations such as punch piercing and dies piercing can be performed after hydroforming while the tub is still mounted in the equipment.

(2) Sectional double-walled tube processing

A product’s overall weight can be reduced through sectional reinforcing.

(3) Flanging

Flanges can be formed for connecting to other parts.

One-piece molding is possible within the hydroforming machine.