Earthquake resistance, high strength, and high corrosion resistance are some of the many features of carbon steel tubes for general structures and building structures, which are described below.

Due to the recent escalation of social demands for safety, economy, scenery, etc., carbon steel tubes of this field are required to have many features such as earthquake resistance, high strength, and high corrosion resistance.

Materials available include:

We have tube-manufacturing equipment that can manufacture tubes up a maximum outer diameter of 609.6 mm as well as a variety of cold drawing equipment allowing us to provide a high level of dimensional accuracy, including for special dimensions.

We also use steel tube manufactured in-house to provide shaped tubes finished in a variety of shapes.

We manufacture products under integrated quality control from raw material design through to the completed product.

Tags and/or stencils are used for identification management of all items. (Customer numbers are displayed as ![]() .)

.)

Some specific examples include:

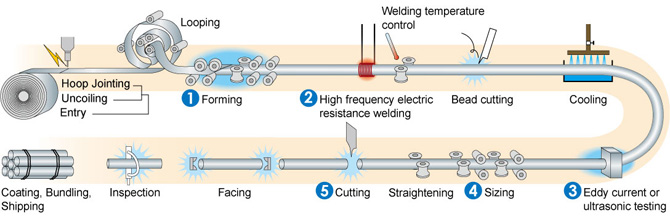

1.FormingRollers with various curvatures are used to bend flat steel strip into a tubular shape. |

|

|

2. High frequency electric resistance welding

|

|

|

3. SizingRollers are used to squeeze the welded tube, adjusting its outer diameter. Rectangular or square tube can be formed in addition to round tubes. |

|

|

4. CuttingCutters are used to cut the continuously formed tube into defined lengths. |

|

|

5. Eddy current testingThe integrity of the raw material and weld zone is completely inspected in a non-destructive means |

|

|