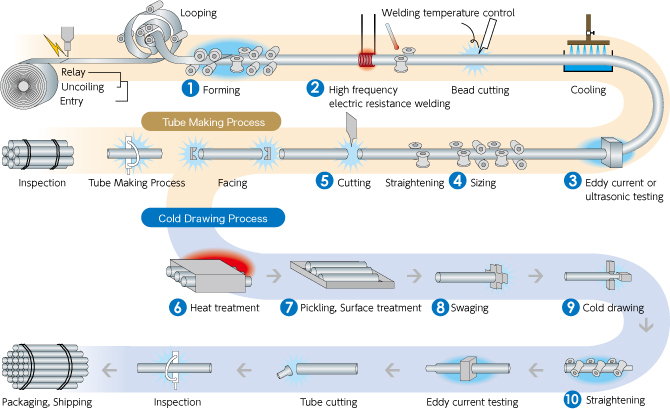

Out of all its numerous features, Nippon Steel Pipe is most proud of its integrated production control system covering tube manufacturing, drawing, heat treatment, and cutting. Whereas many steel tube manufacturers outsource the drawing process, this is yet another area where we exhibit our user-focused characteristics and commitment.

Moreover, as an example of our application of new technology, we are attracting attention for our practical application of a high ductility mill, which produces steel tubes with good workability.

1.FormingRollers with various curvatures are used to bend flat steel strip into a tubular shape. |

|

|

2. High frequency electric resistance

|

|

|

3. SizingRollers with various curvatures are used to squeeze the welded tube, adjusting its outer diameter. Rectangular or square tube can be formed in addition to round tubes. |

|

|

4. CuttingCutters are used to cut the continuously formed tube into defined lengths. |

|

|

5. Eddy current testingThe integrity of the raw material and weld zone is completely inspected in a non-destructive means. |

|

|

6. Heat treatmentThe metallic structure of the high frequency electric resistance welded tube is standardized and softened through heat treatment in a continuous furnace. |

|

|

7. Pickling, Surface treatmentThe surface is roughened through pickling and the tube is put through chemical treatment and dipped in oil. |

|

|

8. SwagingThe end of the tube is swaged, reducing the outer diameter so that it can be inserted into the dies for cold drawing. |

|

|

9. Cold drawingThe tube is drawn through plug dies, creating steel tube with excellent dimensional accuracy and smoothness. |

|

|

10. StraighteningThe straightness of the tube is increased. |

|

|